A hydraulic cylinder is a mechanical device that converts hydraulic energy (the energy of pressurized fluid) into linear mechanical force and motion. It is a crucial component in various types of machinery and equipment, especially in applications where heavy lifting or precise linear movement is required. Hydraulic cylinders are commonly used in industrial machinery, construction equipment, agricultural machinery, and more.

Understanding the proper procedure for purging air from a hydraulic cylinder and its associated system is important for achieving optimal performance.

Here are the key components and how a hydraulic cylinder works:

source: pinterest.com

Cylinder Barrel: This is the main outer body of the hydraulic cylinder. It houses the other components and provides a containment structure for the hydraulic fluid.

Piston: The piston is a cylindrical component that moves inside the cylinder barrel. It is usually sealed with rings to prevent fluid leakage and create a pressure differential. When hydraulic fluid is introduced on one side of the piston, it creates a force that drives the piston in one direction.

Rod: The piston is connected to a rod, which extends outside the cylinder barrel. The rod is what provides the linear motion and force output. It can be attached to the load that needs to be moved or manipulated.

Hydraulic Ports: Hydraulic cylinders have ports that allow hydraulic fluid to be introduced into and removed from the cylinder. By pressurizing one side of the piston and allowing fluid to escape from the other side, you can control the direction of the piston’s movement.

Seals: Sealing elements, such as O-rings or gaskets, are used to prevent hydraulic fluid from leaking out of the cylinder and to maintain pressure differentials on either side of the piston.

Mounting Options: Hydraulic cylinders can be mounted in various ways, depending on the specific application. Common mounting options include trunnion mounts, flange mounts, and clevis mounts.

Hydraulic cylinders come in various sizes and configurations to accommodate different loads and operating conditions. They can be operated using hydraulic pumps, valves, and other hydraulic components that control the flow and pressure of the hydraulic fluid.

The primary advantages of hydraulic cylinders include their ability to provide high force output, precise control of movement, and suitability for heavy-duty applications. They are commonly used in scenarios where other methods of linear motion or force generation, such as pneumatic cylinders or electric actuators, may not be as suitable.

How to Tell if Air is Present in a Hydraulic System

source: pinterest.com

If you notice that the plunger exhibits a soft or erratic, pulsating motion, it’s a clear indication that there is trapped air within the hydraulic system. These undesirable movements are a direct result of the air’s compressible nature, and it is imperative to release this air from the system. In the long run, the presence of air can lead to oxidation, an increase in fluid viscosity, the formation of sludge, depletion of additives, and a rise in acidity levels. Furthermore, the air trapped within the system can trigger cavitation, a phenomenon characterized by the rapid formation of vapor bubbles due to fluctuations in fluid pressure. These bubbles subsequently collapse, giving rise to minor vibrations and shock waves. If this occurs repeatedly, it can potentially cause damage to metallic components within the system.

How Air Gets into a Hydraulic System

Hydraulic oil can become aerated when air infiltrates the system through seals, fittings, or during maintenance procedures. Additionally, it’s important to note that hydraulic fluid inherently contains some dissolved air, which is typically not a concern. However, should cavitation take place, the formation of bubbles during this process can pose a problem.

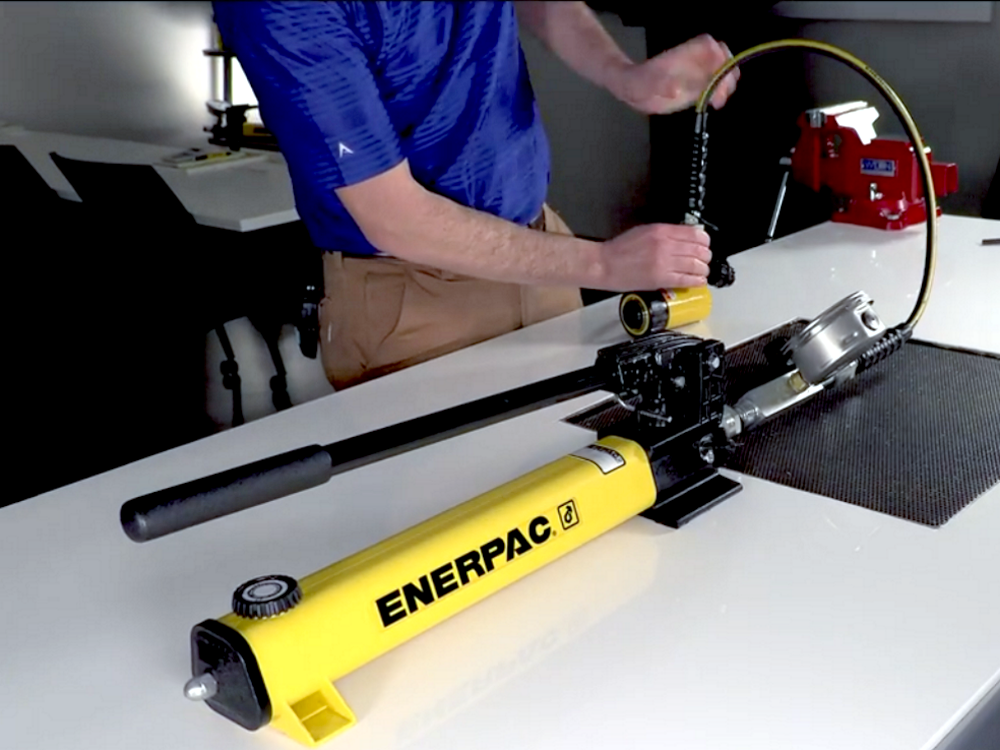

How to Bleed Air from a Hydraulic Cylinder – Step-by-Step Process

source: pinterest.com

Begin by connecting your hose to the cylinder. If the cylinder is devoid of oil, expect the bleeding process to take a bit longer. In the case of a double-acting cylinder, ensure you attach hoses to both couplers and use a double-acting pump.

Next, position the hydraulic cylinder beneath the pump, either by elevating the pump or lowering the cylinder. It’s advisable to orient the cylinder with its ports facing upward, as this will encourage any trapped air to rise toward the pump.

Verify that the hydraulic pump reservoir is properly vented. Operate the cylinder, advancing and retracting it with minimal or no pressure. This initial movement will help you assess whether the cylinder is functioning as intended.

Proceed to repeat the advance and retract cycles several times, closely observing the operation for smoothness. If you detect any indications of jerky, spongy, or pulsating movements, this signals the presence of residual air within the system.

Continue to cycle the cylinder until the plunger’s operation becomes consistently smooth and free from any irregularities.

Where to Purchase Hydraulic Cylinder

If you are seeking hydraulic cylinder compatible with TorcStark tools, you can obtain them from the nearest TorcStark distributor in your area. TorcStark boasts unparalleled expertise in the design and production of hydraulic cylinderer, Hydraulic Torque Wrenches, couplers and bolting tools. In comparison to well-established bolting equipment brands that have been present in Europe and the United States for over a century, we stand out significantly in terms of both product quality and pricing. Presently, TorcStark not only crafts and offers hydraulic tightening tools, but we have also expanded our range to encompass nut bolt tightening tools utilizing electricity and gas as power sources.