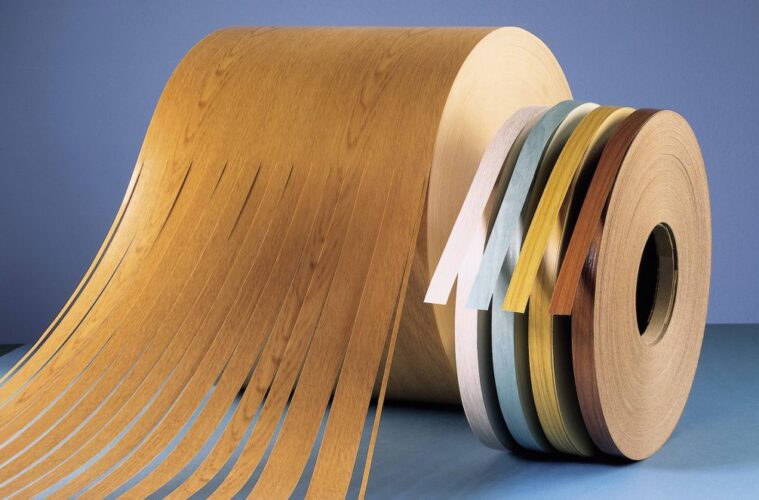

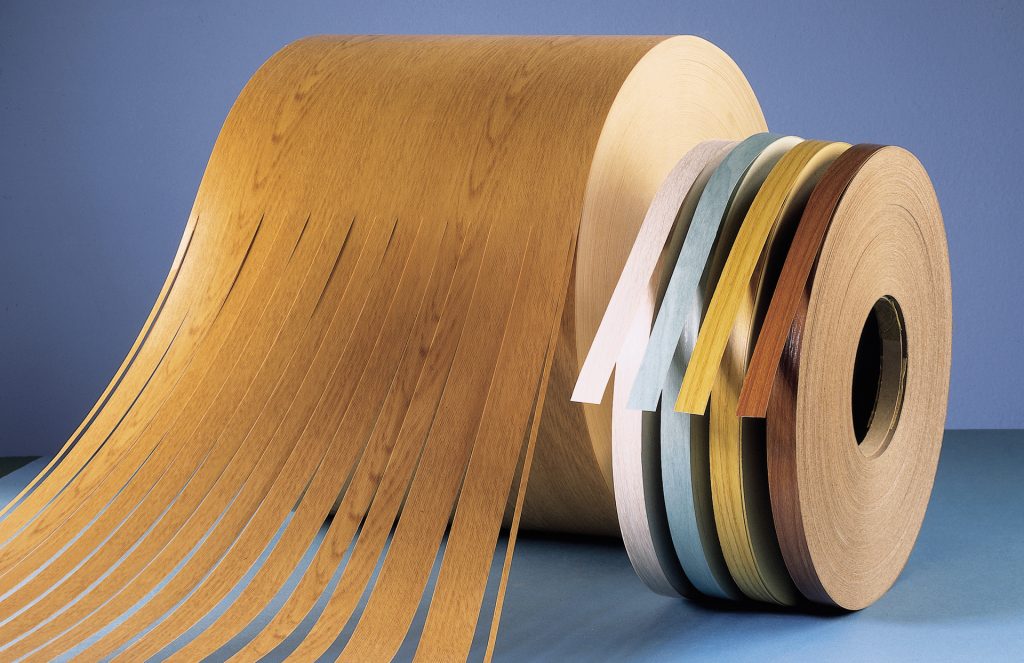

Edgebanding is a woodworking process in which a thin strip of material, typically wood, plastic, or metal, is applied to the edge of a panel or board to cover and protect the exposed edges. This is often done to improve the appearance of the finished product and to make it more durable. Edgebanding can be applied to both raw and finished wood, and is commonly used in the manufacture of furniture, cabinetry, and other wood products. The edgebanding material is typically applied using an edgebander, a specialized machine that trims and shapes the edgebanding to fit the edge of the panel or board. The edgebanding can be applied in a continuous strip, or it can be cut into shorter lengths and applied in pieces. Edgebanding can also be applied using adhesives, heat, or a combination of the two.

How to use edgebanding?

source: pinterest.com

Measure the length of the edge that you want to cover with edgebanding. This will help you determine how much edgebanding material you will need.

Cut the edgebanding material to the appropriate length using a saw or a cutter.

If the edgebanding material is not pre-glued, apply a thin layer of wood glue to the edge of the panel or board.

Place the edgebanding material onto the edge of the panel or board, aligning one edge of the edgebanding with the edge of the panel or board.

Use a clamp or other clamping device to hold the edgebanding in place while the glue dries.

Once the glue has dried, use a trim router or a hand-held trimmer to trim off any excess edgebanding material.

Use a sanding block or sander to smooth out any rough edges or imperfections on the edgebanding.

If desired, you can apply a finish to the edgebanding to protect it and enhance its appearance.

It’s important to make sure that the edgebanding material is properly aligned with the edge of the panel or board, and that it is securely attached with glue or other adhesive. If the edgebanding is not properly applied, it may peel or come loose over time, which can ruin the appearance of the finished product.

What glue to use with edgebanding

source: pinterest.com

There are several types of glue that can be used with edgebanding, depending on the type of edgebanding material and the application method. Here are a few options:

PVA (polyvinyl acetate) glue: This is a common type of wood glue that is suitable for use with most types of edgebanding material. It is strong, water-resistant, and dries clear, making it a good choice for visible edges.

Contact cement: This type of glue is very strong and provides a permanent bond, but it can be difficult to work with because it dries quickly and cannot be repositioned once it has been applied. Contact cement is often used with edgebanding materials that are difficult to glue, such as melamine or PVC.

Hot melt glue: This is a type of glue that is applied using a heat gun or other heating device. It provides a strong bond and is often used with edgebanding machines that apply the edgebanding using heat. Hot melt glue is available in various formulations, including ones that are suitable for use with wood, plastic, and other materials.

It’s important to choose a glue that is compatible with the edgebanding material and the application method. Some edgebanding materials may require special adhesives, such as melamine or PVC, which may require the use of a specific type of glue or adhesive and industrial tape. It’s also a good idea to test the glue on a small piece of scrap material before using it on your project to ensure that it provides the desired bond strength and appearance.

Summary

source: pinterest.com

There are many places where you can buy edgebanding, including online retailers, woodworking stores, and home improvement stores. When shopping for edgebanding, here are a few things to consider:

Material: Edgebanding is available in a wide range of materials, including wood, plastic, and metal. Choose a material that is appropriate for your project and budget.

Color and finish: Edgebanding is available in a variety of colors and finishes to match different wood species and design styles. Consider the color and finish of the edgebanding in relation to the rest of your project.

Thickness: Edgebanding is available in different thicknesses, which can affect the appearance and durability of the finished product. Thinner edgebanding may be less expensive, but it may not provide as much protection or support as thicker edgebanding.

Length: Edgebanding is typically sold in rolls or strips of various lengths. Choose a length that is appropriate for your project, taking into account the length of the edges that you need to cover.

Adhesive: Some edgebanding is pre-glued, while others are not. Consider whether you want to use a separate adhesive or if you prefer the convenience of pre-glued edgebanding.

When shopping for edgebanding, it’s a good idea to compare prices and read product reviews to find the best option for your needs. You may also want to consider purchasing a sample of the edgebanding to test its appearance and compatibility with your project before buying a larger quantity.