The epoxy resin is a thermosetting polymer. This is a very popular product for the creation of resin crafts in Japan today. It comes in a transparent liquid format that can be mixed with different pigments. It changes from a liquid to a solid-state when a hardener or catalyst is applied. People called it in many ways, epoxy resin, epoxy, porcelain or liquid crystal. The most used resin results from the Bisphenol A mixture A and Epichlorohydrin. Here The Architecture Designs explore information about epoxy for wood among other applications.

How to apply epoxy resin

source: do-daddy.com

The pure epoxy is used to protect structures from corrosion, from ships to industrial platforms. The modified epoxy is important as a resin for the protection of steel, tanks, pipes and even chemical plants. It is also used for boat hulls, both in submerged areas and in those above the water. They manage to be even superior to pure epoxies because of their versatility, flexibility and solidity.

The phenolic epoxy is one of the most powerful in the market at higher temperatures. Very good for tank and tank interiors in which you must store hot water, oil and acid materials.

Epoxy plastic, it is very waterproof, environmentally friendly, they have great performance. It is very good in low-temperature environments.

Epoxy for surfaces is difficult to use. It is not in the right conditions due to extreme humidity conditions. In cases, where some layer has not been repaired well, this type of epoxy resin may be very necessary.

There are more ways to use epoxy resin for polyester manufacturers. This is simply proof of how it resists abrasion under extreme conditions and how solid materials can reinforce this type of resin.

Advantages of epoxy resin

source: pinterest.com

Thanks to the brightness, transparency and hardness they make epoxy resin one of the most used materials in the floor covering for qualities such as:

Resistant to high temperatures

Thanks to the epoxy resin composition it can withstand prolonged temperatures up to 45º without problems and in short times up to 70º. Users can use the best outdoor epoxy resin to cover their house and avoid the extreme heat of the sun.

Corrosion resistance

As we said above is a material used in shipbuilding, withstanding prolonged exposure to corrosive chemical agents.

Ideal for high traffic floors

The physical resistance of the epoxy resin of 65N per m2 makes it the ideal material for industrial floors, warehouses, garages or processing plants. Enduring without problem all the movement of heavy material from these sites. It has a lifespan of up to 40 years.

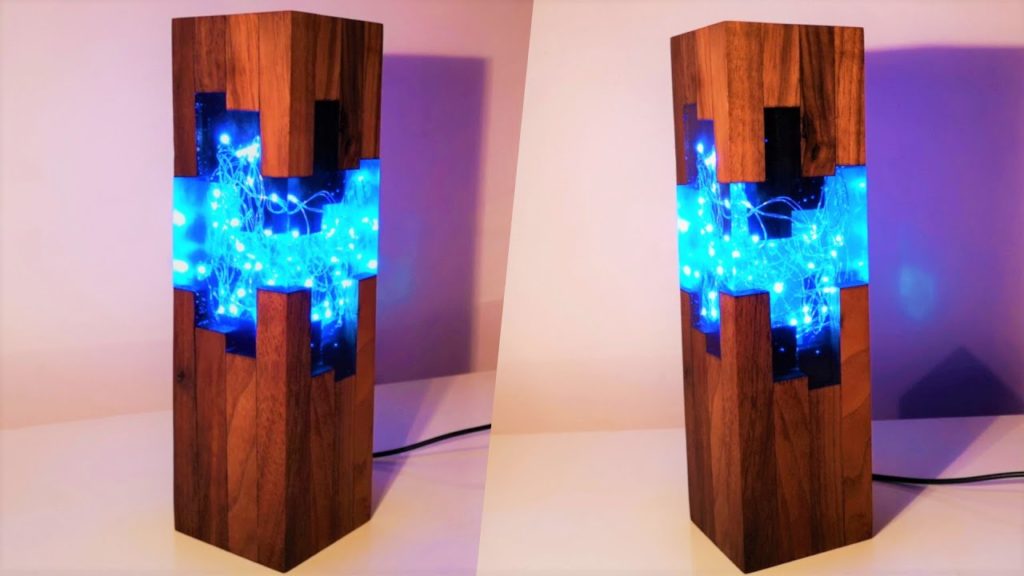

source: woodtouchus.com

Easy cleaning and application

Epoxy resin coatings are easily applied and cleaned comfortably due to their perfect flexibility, wetting and adhesion. It is also anti-bacterial, repels dust and is easily cleaned with water with zero soap or just water.

Self-leveling and does not shrink

The epoxy resin barely shrinks with temperature changes. It is not combustible or emits toxic substances. In addition, the absence of solvents causes the epoxy resin to level along the entire surface, leaving a completely smooth floor, without cracks and no joints.

Multi-purpose

In addition to floors, we use epoxy resin to create countertops, tables, and pools or even bar bars. You can see in resin products, apart from being used in many more fields as we have seen above. Also, for resin craft ideas you can check Crafters Diary.

source: youtube.com

Radiant

Liquid crystal floors are equipped with modern technology, allowing the installation of the radiant floor without the floor suffering at any time.

100% legal for business

The epoxy resin, being non-slip, complies with the regulations for industrial kitchens and stores for sale to the public, including also the inspection of PRL (occupational risk prevention).

What is an epoxy resin for?

Epoxy resin has many applications, such as engineering adhesive. Its use is widespread in the construction and repair of all types of vehicles, cars, motorcycles, bicycles, and airplanes.

source: shopify.com

In the use of electronics and electricity, to avoid short circuits, many parts are encapsulated with epoxy resin to protect them from dust and moisture.

In boats and surfboards, practically all types of instruments exposed to corrosion by sea salt, humidity and sun can benefit from the protection of epoxy resin. It together with the polyester gel, even sun protection is total for boats, yachts, boats, surfboards, etc.

In the construction of molds, these materials composed of resin and catalysts are perfect for the manufacture of molds being these cheaper than those produced by metal or wood. The food industry uses epoxy resin in tomato cans to avoid corrosion by tomato acid is not saved.