In the realm of construction projects, shop drawings stand as vital blueprints that bridge the gap between design concepts and practical execution. Unlike generic architectural or engineering plans, shop drawings delve into specific components, systems, or structures of a project, offering detailed instructions for fabrication, assembly, and installation. They serve as the “how-to” manuals, answering critical questions regarding materials, dimensions, tolerances, and assembly processes. Let’s delve deeper into the significance and intricacies of shop drawings.

Components of Shop Drawings

Shop drawings encompass various components tailored to different aspects of a project:

1. Architectural:

source: shoeyay.blogspot.com

Architectural shop drawings focus on elements such as cladding, interior finishes, and other aesthetic features crucial for the visual appeal and functionality of a structure.

2. Structural:

Structural shop drawings delve into the detailed specifications of structural components like steel frames, providing instructions for fabrication, assembly, and erection.

3. MEP (Mechanical, Electrical, Plumbing):

MEP shop drawings elaborate on the intricate details of mechanical systems, electrical wiring, and plumbing layouts, ensuring seamless integration and functionality within the overall structure.

Each component plays a crucial role in translating design intent into tangible construction elements, facilitating efficient project execution.

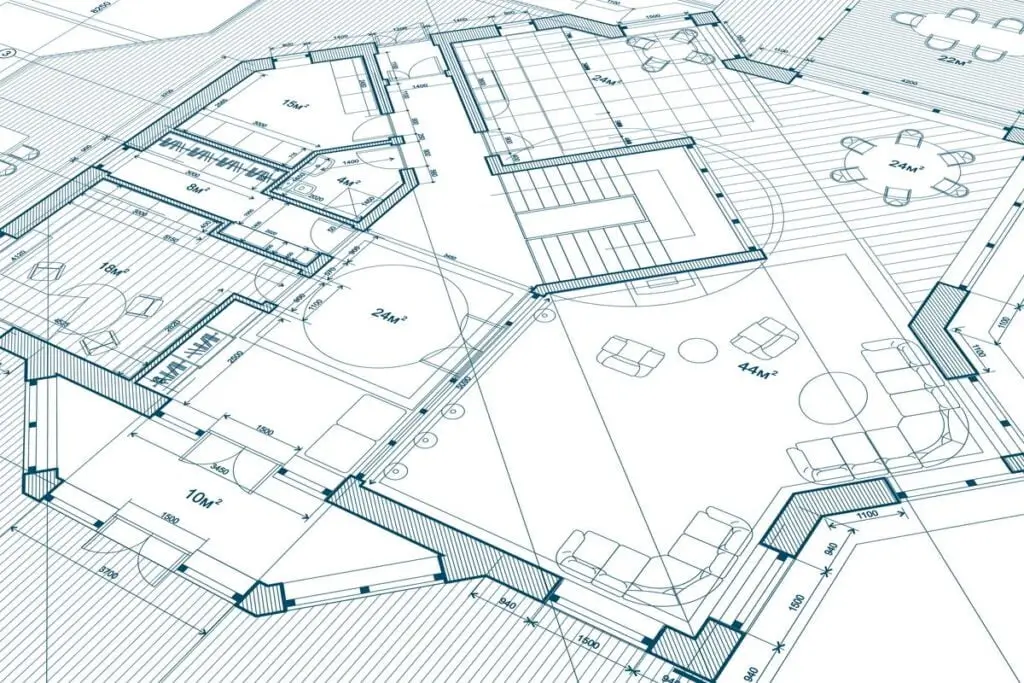

The Importance of Shop Drawings in Construction

source: Pinterest.com

Shop drawings play a pivotal role in enhancing project efficiency and communication by:

Enhancing Project Efficiency and Communication:

By serving as a common language between design and construction teams, shop drawings ensure seamless coordination and alignment of project goals, minimizing misunderstandings and discrepancies.

Preventing Errors and Minimizing Rework:

Detailed shop drawings help identify potential issues and clashes early in the process, minimizing costly errors and rework during fabrication, assembly, or installation.

Streamlining Project Management and Resource Allocation:

source: Pinterest.com

Shop drawings provide clear guidelines for resource allocation and scheduling, enabling project managers to optimize workflows and ensure timely completion within budget constraints.

Shop Drawings vs. Construction Drawings

While construction drawings outline the overall design intent and spatial arrangements, shop drawings delve into the specific details necessary for fabrication, assembly, and installation. While construction drawings focus on broader concepts, shop drawings provide granular instructions tailored to individual components or systems, ensuring precision and accuracy in execution. Techture provides

Challenges and Solutions in Managing Shop Drawings

source: bibloteka.com

Despite their significance, managing shop drawings poses several challenges, including miscommunication, changes in design, and tight project deadlines. Effective communication and collaboration among all stakeholders are essential for navigating these challenges successfully. Additionally, leveraging digital tools and technologies can streamline the review and approval process, enhancing efficiency and accuracy.

In essence, shop drawings serve as the backbone of construction projects, translating design concepts into actionable plans for fabrication and construction. Understanding the intricacies of shop drawings is paramount for ensuring project success, minimizing errors, and maximizing efficiency throughout the project lifecycle. As construction methodologies evolve, so too will the landscape of shop drawings, driving innovation and efficiency in the construction industry.