Introduction

Are you a beginner or someone who wants to improve their skill in TIG welding but lack the proper knowledge? Well, you should know that it’s not an easy task to master in TIG welding.

Anyway, to be an expert in TIG, what you must possess at first is a prominent level of patience. With calmness and patience, you must follow the necessary steps for proper welding.

However, you shouldn’t worry much about those steps as we are going to introduce you to 10 tips and tricks of TIG welding. With these ideas, you will be confident enough for the welding job.

So, let’s get you on track with these amazing tips at The Architecture Designs.

10 tips and tricks of TIG welding

source: vimeocdn.com

Take a look at the following tips and tricks that are definitely going to make you a skilled person in TIG welding.

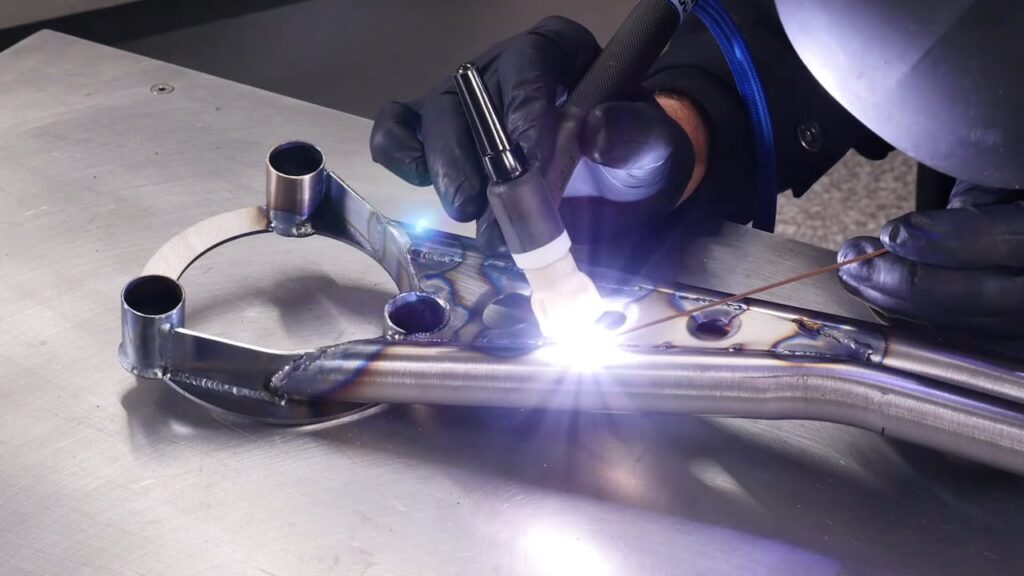

Keep the surface cleansed

The first thing in TIG welding is a clean surface to work on. Because metal must be cleaned for appropriate welding if you want to make a strong arc as well as a solid weld.

However, you can easily do the job with a stainless steel brush. Hence, to get great quality from the welding, it’s always better if you spend more minutes cleaning the metal.

Employ the right kind of tungsten

source: dynaweld.com.au

You should know that, for different surfaces or metals, you will require different tungsten. And there are mainly two types of tungsten electrodes- green and red.

So, when working with aluminum material, use the green electrode to weld. On the other hand, always works with the red tungsten when you are welding with the steel.

However, there is another type of tungsten electrode known as E3 purple that can be associated with any type of metal. But, try to stick to the red and green electrodes to work with.

Apply the correct shielding gas

To protect the molten weld pool from exposure to oxygen, hydrogen, or nitrogen, the proper shielding gas is mandatory. And the most frequent shielding gas is 100% argon. The mixture of argon and helium is another popular available shielding gas to be used in welding.

However, never try to work with the helium gas alone as it might make it difficult to weld with. Hence, while welding, just set the shielding gas at 15 to 20 cubic feet/hour for a safe function.

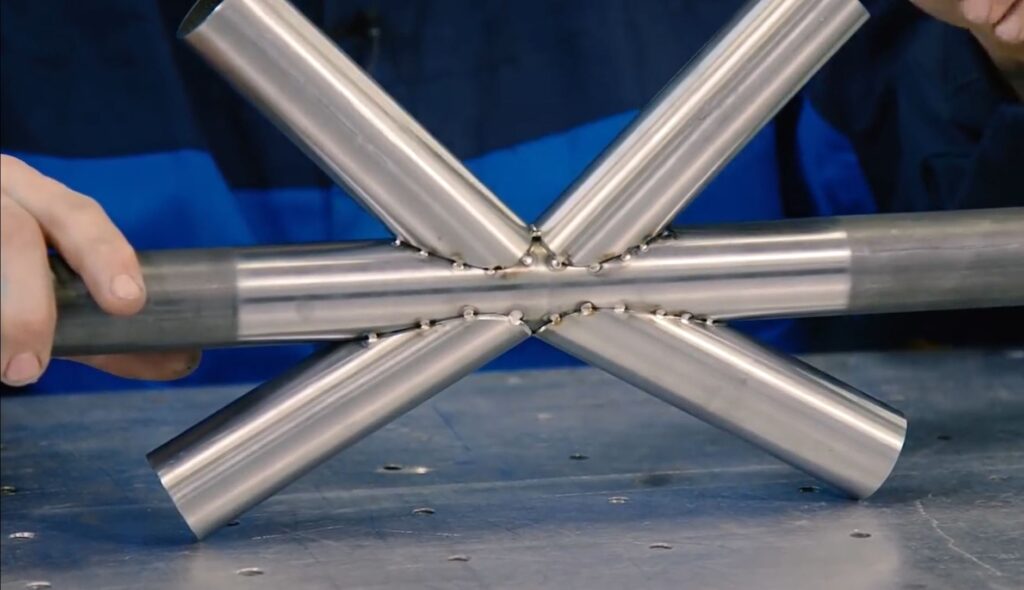

Pick larger rods

source: beginnerweldingguide.com

If the torch angle, as well as the arc length, are accurate in welding, then perhaps it’s because of the rod size. Because the larger the rod is, the easier it is to feed. Thus, it provides a better TIG welding.

However, beginners should exercise on 1/16 inches to 1/8 inches wide metal. And standard TIG welding rods are usually 1/16- or 3/32 inches in diameter. Besides, always try to use thicker rods for thick metals and thinner rods for thin metals.

Grinding the electrodes properly

Before using the tungsten electrode in TIG welding, you have to arrange it through the grinding process. So, just carefully grind the tungsten in a lengthwise procedure.

However, most of the beginners use a bench grinder to do the task but they have to make sure that they won’t employ it on other kinds of metals. On the other hand, professional welders use a tungsten sharpener to get the job done.

Wear an appropriate safety equipment

It’s been found that the tungsten electrodes emit a bit of radiation. Hence, make sure to wear a respirator while you are working with the TIG welder. It will not only protect your nose but also your mouth as it’s specially designed for air passageway protection.

Moreover, you should also look out to make less dust from grinding in your area. And check whether the working place has an adequate ventilation system or not.

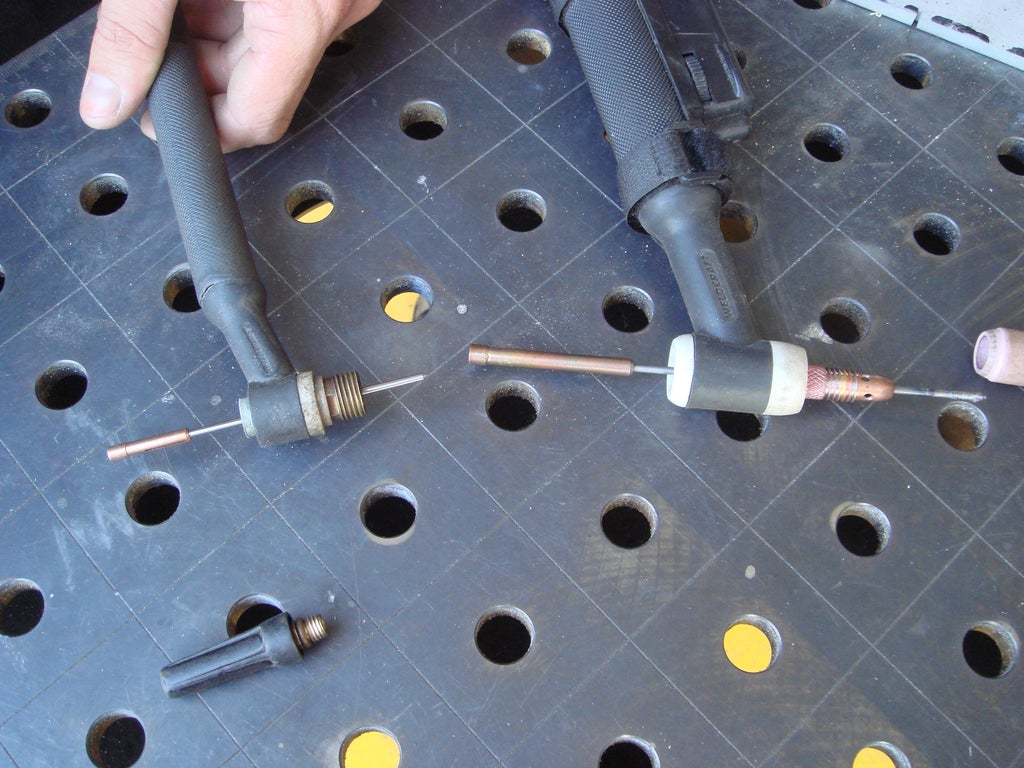

Regrind the electrode when necessary

source: instructables.com

While working with the TIG welder, if you dip your tungsten in the puddle and get it contaminated, then you must need to regrind its tip or choose another fresh one to work with. Otherwise, it will influence the quality of the welding.

Besides, the electrodes might develop the ball gradually which can affect the arc and ruin the work’s standard. So, you need to have as much tungsten as possible when welding.

Maintain the rod and torch angle

People often make mistakes with improper torch angle and rod angle. If both the angles are kept at the same point, then it might make the heat deflect while working. As a result, the rod will start to melt even before it hits the weld pool.

So, keep the torch at an angle of 10 degrees or less and make sure to feed the rod into the welding pool.

Concentrate intensely

TIG welding is such a kind of process where you need to be 100% focused on your entire work. Because distraction will not only reduce your quality of welding but also might cause accidents which you surely want to avoid.

So, try to eliminate any kind of interruption or distraction from your working environment and concentrate on your task from start to end. Always attempt to keep some additional filler rods so that you won’t have to distract from finding them.

Steadily reduce the arc

source: weldingpros.net

To produce the heat for welding, a foot paddle is required for the control of current flow through the rod. So, while working with the temperature, always keep the foot paddle about ¾ of the way down.

As a result, you can steadily release the arc. Because a sudden shutting down of the arc might lead to cracking which you will always want to ignore.

Verdict

Finally, we learned a lot of ideas regarding TIG welding. I hope the mentioned 10 tips and tricks of TIG welding will help you out in your next welding task.

Just remember that it’s normal to take time to learn proper TIG welding. And you might find it frustrating too. But, with practice and patience, you can definitely reach your goal.