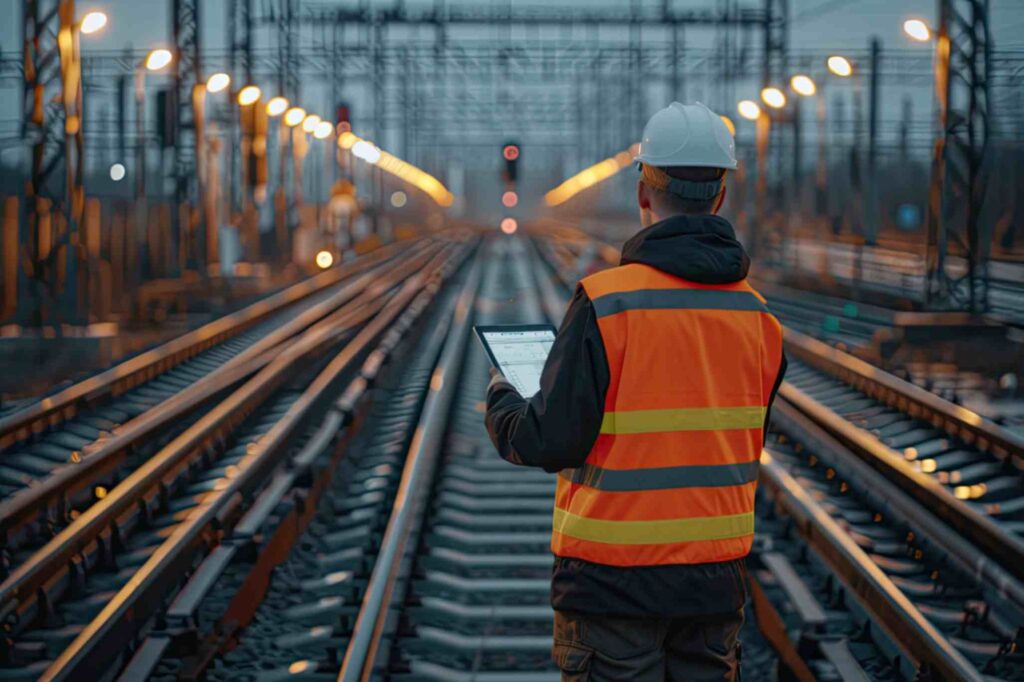

Railroad signals are key to keeping trains safe and on track. They guide trains through complex routes, making sure passengers and freight move smoothly. Keeping these signals in top shape, alongside regular rolling stock maintenance, is a big job that requires a lot of skill and focus.

This article looks into how railroad signal maintenance keeps the trains running safely and reliably. We’ll cover why signal systems are so important, the rules they follow, and the new tech changing the game. We’ll see what makes this job so critical to the rail industry.

Key Takeaways

- Railroad signal maintenance is critical for ensuring the safe and efficient operation of trains.

- Signals play a crucial role in rail operations, governing the movement and control of trains.

- Regulatory standards and guidelines provide the framework for maintaining signal systems.

- Preventive and corrective maintenance strategies are essential for keeping signals functioning reliably.

- Advanced technologies are transforming the way railroad signal maintenance is conducted.

Understanding the Importance of Railroad Signal Maintenance

The Critical Role of Signals in Rail Operations

Train control signals are vital for safety. They tell train operators when to stop, slow down, or go. These signals work with other systems to make sure trains move safely.

Consequences of Signal Failures and Malfunctions

If railroad signals don’t work right, the effects can be huge. Failures can cause trains to crash, derail, or stop running. This puts people and goods at risk. It can also lead to injuries, deaths, and big losses for the rail industry and communities.

So, keeping railroad signals working well is a top goal. Operators need to check them often and fix problems fast. This helps avoid the dangers of signal failures and keeps rail travel safe and reliable.

“Proper signal maintenance is crucial, as signal failures or malfunctions can lead to disastrous consequences, such as train derailments, collisions, and service disruptions, which can result in injuries, fatalities, and significant economic losses.”

Regulatory Standards and Guidelines for Signal Maintenance

The rail industry follows strict rail industry regulations and signal maintenance standards. These come from agencies like the Federal Railroad Administration (FRA) and the American Railway Engineering and Maintenance-of-Way Association (AREMA). These federal rail regulations set the rules for checking, testing, and keeping signal systems safe and reliable.

To meet signal system compliance, rail companies must follow detailed guidelines. They need to check signal parts often, like track circuits and signal lights. It’s also key to test and maintain them to spot and fix problems early.

| Regulatory Agency | Key Signal Maintenance Standards |

| Federal Railroad Administration (FRA) |

|

| AREMA |

|

Following these rail industry regulations and signal maintenance standards is crucial. It keeps the rail network safe and ensures passengers and cargo are secure. By doing so, rail operators can reduce the chance of signal failures and keep their rail systems running smoothly.

Key Components of a Railroad Signal System

Railroad signal systems are key to keeping trains safe and moving smoothly. They have many important parts, each doing its part to control train traffic. Let’s look at the main parts of a railroad signal system.

Signal Lights and Aspects

Signal lights are a big part of railroad signal systems. They show different colors and patterns, or “aspects,” to tell train engineers important info. Each aspect tells them things like how fast to go or if they should stop or keep going. It’s key for train operators to know these signals to keep things safe.

Track Circuits and Control Systems

Track circuits and control systems are also vital. They use electrical circuits to see if trains are on the tracks. This makes the right signal lights and switches turn on automatically. It helps keep trains apart and stops collisions.

The control systems let people check and change the signal parts from far away. This means they can fix problems fast and keep the trains running well. By watching the track circuits and changing the signals as needed, these systems keep rail travel safe and reliable.

Together, the parts of a railroad signal system make a system that keeps trains safe and moving well. From the lights that guide train engineers to the systems that watch and manage train traffic, each part is key. They all work together to make rail travel reliable and safe.

Preventive Maintenance Strategies for Signal Systems

Routine Inspections and Testing

Regular checks and tests are the heart of good maintenance. They include looking over signal parts, making sure they work right, and watching system data closely.

- Periodic visual inspections of signal lights, control cabinets, and trackside equipment to identify any signs of wear, damage, or deterioration.

- Comprehensive signal testing procedures to validate the functionality of each system component, from track circuits to switch controllers.

- Ongoing monitoring of signal system data, such as current draw, voltage levels, and communication diagnostics, to detect any anomalies or emerging issues.

By using these railroad signal preventive maintenance methods, rail companies can fix problems before they start. This helps keep trains running safely and reliably.

“Preventive maintenance is the key to maximizing the lifespan and performance of railroad signal systems. Regular inspections and testing help us stay ahead of potential issues and maintain the highest levels of safety and reliability on our rail network.”

– Mark Johnson, Director of Signal Maintenance, Union Pacific Railroad

Corrective Maintenance Procedures for Signal Issues

When railroad signals fail, maintenance teams must work fast. They need to find the problem, figure out why it happened, and fix or replace it. This process, called corrective maintenance, keeps the rail network safe and reliable.

The first step is a detailed check of the signal system. Teams use special tools and methods to find where the issue is. It could be a broken part, wiring problems, or track circuit issues.

After finding the cause, the team plans how to fix it. This might mean replacing parts like light bulbs or doing bigger work on the whole system. The aim is to get the signals working again safely and fast.

| Corrective Maintenance Procedure | Description |

| Troubleshooting and Diagnosis | Using specialized tools and techniques to identify the root cause of the signal issue or failure. |

| Component Repair or Replacement | Repairing or replacing individual signal components, such as light bulbs, lenses, or circuit boards. |

| System Overhaul | Performing more extensive work to overhaul the entire signal system and restore it to full functionality. |

By using these corrective maintenance procedures, teams can fix signal problems fast and well. This keeps trains running smoothly and keeps everyone safe.

Railroad Signal Maintenance: Ensuring Safety and Reliability on the Tracks

Keeping railroad signal systems in top shape is key for safety and reliability in train operations. Following strict rules, using proactive maintenance, and fixing signals quickly helps reduce accident risks and keeps trains running smoothly. This keeps passengers and goods safe and trains moving on time.

Good railroad signal maintenance importance means checking, fixing, and keeping signals working right. This keeps the complex system of signal lights, track circuits, and control systems running well. It guides trains safely through the rail network.

Checking signals often and fixing problems early stops big issues before they start. Preventive maintenance strategies, like cleaning and replacing parts, make signals last longer and work better. This cuts down on sudden failures.

- Regularly check signal lights and track circuits for any problems.

- Have a plan for regular cleaning, oiling, and replacing parts.

- Have a detailed plan to fix signal problems fast, reducing train delays.

Putting railroad signal maintenance importance first helps keep rail travel safe. It builds trust with passengers and shippers. This careful planning makes the rail network more reliable and helps the industry grow and succeed over time.

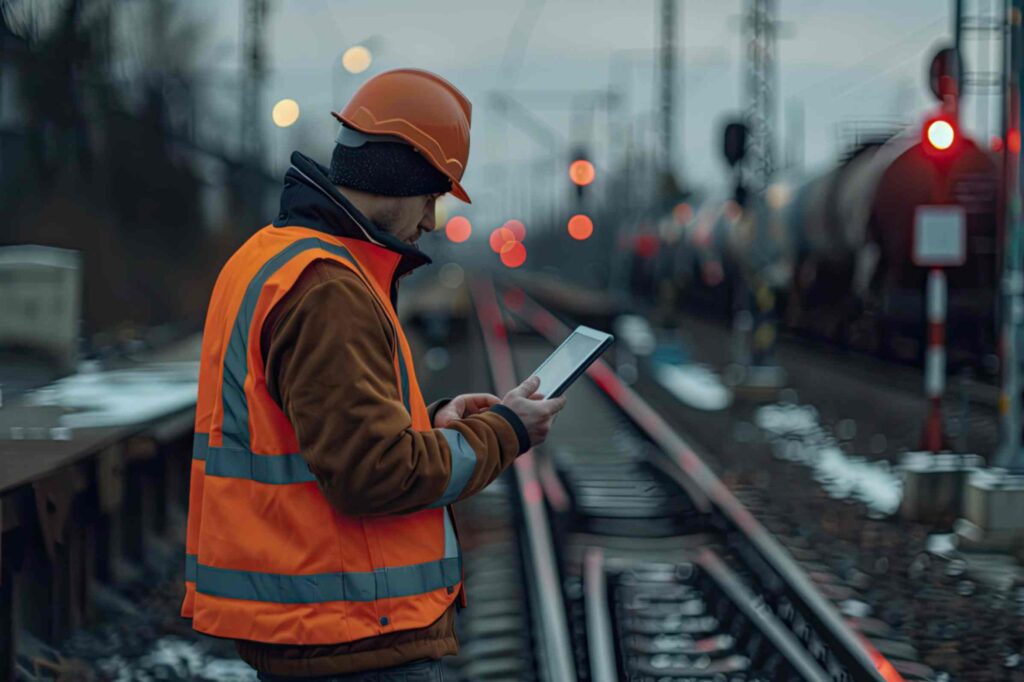

Advanced Technologies in Railroad Signal Maintenance

The railroad industry is now using the latest technologies to improve how signals are maintained. These new tools let maintenance teams check on signal systems from afar. They can get alerts in real-time and fix problems fast from one place.

Remote Monitoring and Diagnostic Tools

These new technologies are changing how we maintain railroad signals. Now, teams can watch how signals work and fix problems before they get worse. They use tools that help them find and fix signal issues quickly.

Using railroad signal maintenance technology, remote monitoring, and diagnostic tools makes fixing signals better and faster. These tools automate and make maintenance easier. This means signals work better and trains run safely.

As railroads keep getting better, using these new technologies is key. They help keep signals working right and make maintenance better. With these tools, railroads can fix problems early, plan maintenance well, and keep trains safe and on time.

Training and Certification for Signal Maintenance Personnel

Keeping railroad signals working well needs skilled people. These workers must learn special skills to check, fix, and keep up the complex systems. They need training to handle the technology and parts of these systems.

To keep trains safe, signal workers need special certifications. These prove they know how to fix signal problems and keep them running right. They learn about railroad signal maintenance training and how to stop issues before they start.

Certified Signal Technicians

The rail industry has set up training programs for signal workers. Certified signal technicians learn to:

- Know how signal system parts work

- Follow rules for keeping signals in good shape

- Do tests and fix signal problems

- Find and fix signal issues

- Use maintenance to keep signals working well

These certifications show the technician’s effort in improving the rail industry. They work hard to keep trains safe and running smoothly.

| Certification | Scope | Renewal |

| FRA-Certified Signal Technician | Comprehensive training on all aspects of signal system maintenance, including electronic, electromechanical, and microprocessor-based technologies. | Every 3 years |

| AREMA Signal Maintenance Certification | Focuses on adherence to industry standards and best practices for signal system installation, testing, and troubleshooting. | Every 2 years |

Training and certifying signal workers helps railroads run safely and efficiently. This helps the whole rail industry workforce do well.

Challenges and Best Practices in Signal Maintenance

Keeping railroad signals in top shape is all about balancing safety and efficiency. Teams face the tough task of following strict safety rules while keeping trains running smoothly. They work hard to overcome the railroad signal maintenance challenges without causing delays.

One big challenge is doing safety checks without slowing down trains. Maintenance teams must plan ahead and talk well to keep operations flowing. They aim to work on signals without stopping trains too often.

Implementing Maintenance Best Practices

To tackle these issues, railroads use maintenance best practices. These include:

- Regular checks and tests to stop problems before they start

- Good communication among maintenance, operations, and regulators

- Using new tech for quick fixes and monitoring

- Training and certifying maintenance staff to keep skills sharp

By following these practices, railroad signal maintenance teams can keep the rail network safe and efficient. This ensures trains run well without delays.

“Maintaining railroad signals is a delicate dance between safety and productivity. The key is finding innovative ways to keep the tracks running smoothly while never compromising on crucial safety protocols.”

The Role of Signal Maintenance in Achieving Operational Excellence

Effective railroad signal maintenance is key to operational excellence in the rail industry. It keeps signal systems reliable and safe. This reduces service problems, boosts on-time performance, and makes rail services more efficient and competitive .

Good signal maintenance lets trains move safely and efficiently. It lowers the chance of accidents and delays. This means better rail industry performance and happier customers. Plus, it helps rail companies save money and make more profit.

To get the best from signal maintenance, rail companies should:

- Regularly check and test signal parts

- Replace old or broken equipment quickly

- Fix signal problems fast

- Keep maintenance staff up to date

- Work with regulators to follow industry rules

By focusing on railroad signal maintenance, rail operators can make their services more reliable and efficient. This helps them succeed in the long run and reach operational excellence in the rail industry.

| Key Metric | Before Signal Maintenance Optimization | After Signal Maintenance Optimization |

| On-Time Performance | 85% | 92% |

| Service Disruptions | 20 per month | 12 per month |

| Maintenance Costs | $500,000 per year | $450,000 per year |

The table shows how effective railroad signal maintenance can really help. It leads to better operational excellence and rail industry performance.

Case Studies: Successful Signal Maintenance Programs

Enhancing Safety and Reliability at BNS Railway

BNS Railway, a big operator in North America, had signal failures that caused delays and safety worries. They changed their approach to signal maintenance to be more proactive. They started doing regular checks, tests, and used tech to watch the system from afar. This helped them fix problems early, cut down on delays, and made the system more reliable.

| Key Metrics | Before Signal Maintenance Program | After Signal Maintenance Program |

| Signal Failures | 120 per year | 45 per year |

| Operational Delays | 1,800 hours | 650 hours |

| Maintenance Costs | $1.2 million | $850,000 |

BNS Railway’s new signal maintenance plan made the system safer and more reliable. It also saved money and made operations better.

Optimizing Signal Systems at ABC Railroad

ABC Railroad, a top freight carrier, knew keeping signals in good shape was key to doing well. They used the latest tech like predictive analytics and remote checks to make their signals better. This let them fix problems before they happened, cut down on unplanned maintenance, and reduce delays.

“The implementation of our signal maintenance program has been a game-changer for ABC Railroad. We’ve seen a marked improvement in system reliability, which has translated into enhanced safety, on-time performance, and cost savings.”

– Emily Harris, Director of Signal Maintenance, BNSF Railway

These stories show how important good signal maintenance is in the railroad world. By focusing on preventing problems, using new tech, and always looking to get better, top rail companies are setting high standards for keeping signals and operations running smoothly.

Future Trends and Innovations in Signal Maintenance

The railroad industry is always changing, and so is how we maintain signals. New technologies are making signal maintenance more efficient, effective, and reliable. Automation, artificial intelligence, and predictive analytics are changing the game in railroad signal maintenance trends.

Automated systems are becoming key in signal maintenance. They can check signals, find problems, and fix them quickly and accurately. This means railroad operators can work smarter, cut down on mistakes, and keep signals working well.

Artificial intelligence (AI) and machine learning are also big players. They help predict and fix problems before they start. By looking at lots of data, AI can spot trends, predict when equipment might break, and suggest maintenance plans. This is changing how we handle signal maintenance.

The future of signal maintenance looks bright with new tech. We’ll see more remote monitoring and self-healing signals. These innovations will make rail operations more reliable and resilient.

“The future of railroad signal maintenance is not just about fixing what’s broken; it’s about anticipating and preventing issues before they even arise.”

As we move forward with railroad signal maintenance trends, safety, efficiency, and doing things better will be key. By using new technologies, railroads can keep their signal systems up to date and ready for the changing transportation world.

Conclusion

Keeping railroad signal systems in good shape is key to safe and reliable train operations. By following strict rules, train operators can make sure their signals work well. This leads to better train services that are safe, efficient, and dependable.

Signal maintenance is very important for keeping trains running safely. It helps protect passengers and goods. Regular checks, fixing problems early, and quick repairs help avoid signal failures. These failures could lead to big safety and reliability issues.

The rail industry is always changing. Using new technologies and best practices in signal maintenance is vital. By training staff and certifying them, train operators can keep up with the latest standards. This makes them leaders in keeping trains safe and running smoothly.

FAQ

What is the importance of railroad signal maintenance?

Railroad signals are key to train safety. They control train movement, keep trains apart, and prevent crashes. Keeping signals working right is crucial. Without it, trains might crash, causing injuries, deaths, and big economic losses.

What are the key components of a railroad signal system?

Railroad signals have lights that show different colors and patterns to train engineers. They also have track circuits and control systems. These systems detect trains and control the signals automatically.

What are the regulatory standards and guidelines for signal maintenance?

The FRA and AREMA set strict rules for signal maintenance. These rules cover how to inspect, test, and maintain signals. They make sure rail operations are safe and reliable.

What are the preventive maintenance strategies for railroad signal systems?

To keep signals working well, maintenance teams do regular checks and tests. They look for problems early to fix them before they cause trouble. This includes checking signals visually and testing how they work.

How are corrective maintenance procedures for signal issues handled?

When signals fail, maintenance teams follow a plan to fix them. They find the problem, fix it, and make sure signals work right again.

What advanced technologies are used in railroad signal maintenance?

Railroads use new tech to keep signals in top shape. They use tools that let crews check signals from afar. This helps them fix problems fast and efficiently.

What are the training and certification requirements for signal maintenance personnel?

Signal maintenance workers need special training and certifications. They learn how to check, test, and fix complex signal systems. This makes sure they can do their job well.

What are the key challenges and best practices in signal maintenance?

Signal maintenance teams have to balance safety with keeping trains running on time. By planning ahead and using new tech, they can keep rail operations safe and reliable.

How does signal maintenance contribute to operational excellence in the railroad industry?

Good signal maintenance is key to running trains well. It cuts down on delays, helps trains run on time, and makes rail services better and more competitive.

What are the future trends and innovations in signal maintenance?

The future of signal maintenance looks exciting. We’ll see more automation, AI, and predictive analytics. These will make rail operations more efficient and reliable.