The innovative realm of architectural design has always been in the pursuit of new, exciting techniques to shape and sculpt the environment we inhabit. One such pioneering technique is water jet cutting, a technology that has redefined the boundaries of creativity and precision in architecture. This powerful tool utilizes a high-pressure stream of water, often mixed with abrasive substances, to cut through a variety of materials with utmost precision.

A Closer Look at Water Jet Cutting

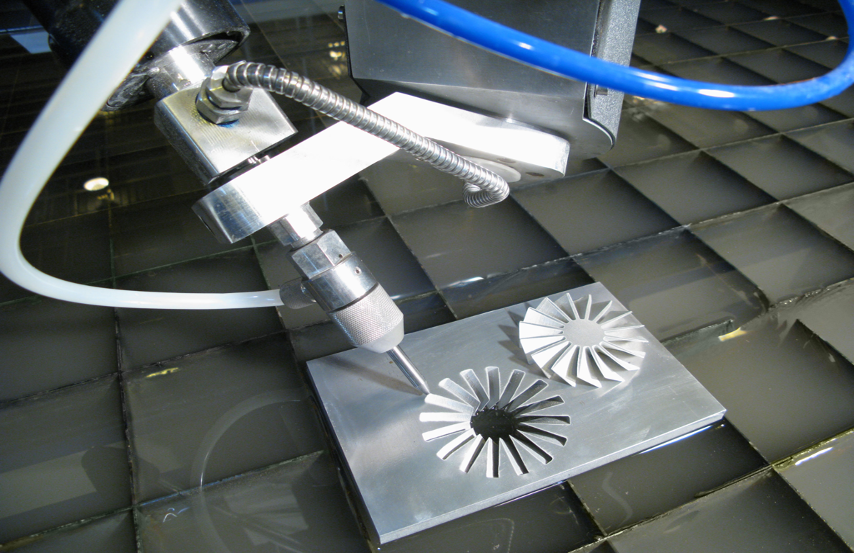

Water Jet Cutting, often abbreviated as WJC, is a technique used primarily for cutting hard materials like stone, metal, and glass. It’s a cold cutting process that uses a high-pressure stream of water to erode a narrow line in the material. In some cases, to increase the cutting power, an abrasive substance such as garnet or aluminum oxide is added to the water stream. This technique is popular due to its accuracy, flexibility, and the fact that it doesn’t produce heat-affected zones (HAZ) in the material being cut.

The Role of Water Jet Cutting in Architecture

The application of WJC in architecture is multifaceted and expansive. It offers architects a powerful tool that can shape nearly any material with extraordinary precision. This technology enables architectural design to go beyond traditional limitations, transforming the creative process and resulting in more innovative, precise, and aesthetically pleasing designs.

Precision and Versatility in Design

Water jet cutting machine provides unparalleled precision and versatility in design. It allows architects to cut intricate patterns and complex shapes out of a range of materials, something traditional cutting tools may struggle to achieve.

Precision: WJC ensures high precision, which is key in architectural design where millimeter-level accuracy can make a significant difference in the outcome.

Versatility: WJC can cut through virtually any material, from glass to steel to stone. This versatility allows architects to experiment with a variety of materials in their designs.

Sustainability and Efficiency

In addition to design capabilities, water jet cutting also offers significant environmental and efficiency benefits.

Sustainability: Since WJC is a cold cutting process, it doesn’t create heat-affected zones or release harmful gases, making it a more eco-friendly choice compared to traditional cutting methods.

Efficiency: WJC can cut materials faster and more accurately, reducing waste and saving time during the construction process.

Case Studies Demonstrating the Impact of Water Jet Cutting in Architecture

There are numerous examples where WJC has transformed architectural design and construction. Let’s look at some of these case studies.

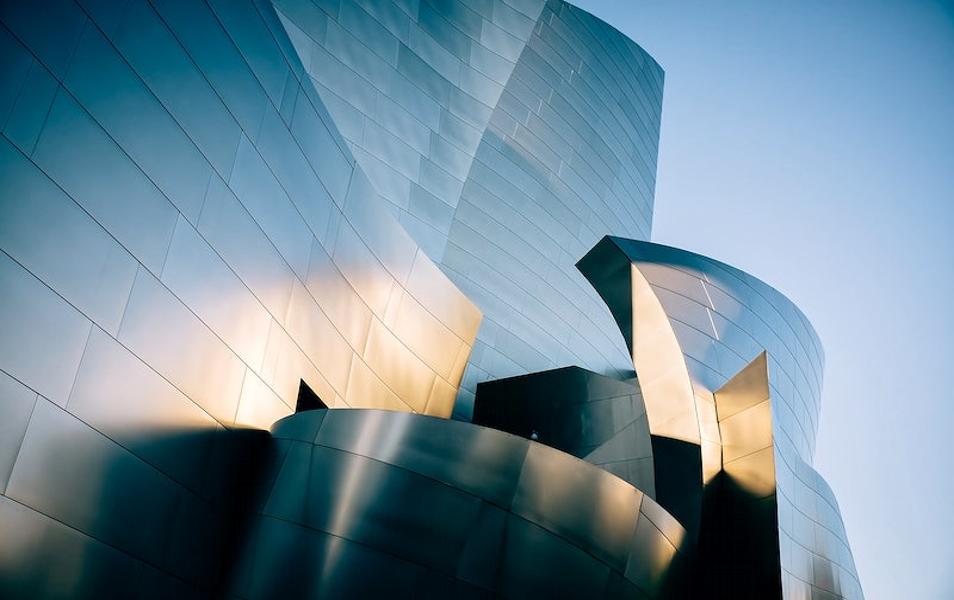

The Guggenheim Museum Bilbao

The Guggenheim Museum Bilbao in Spain is an architectural marvel designed by renowned architect Frank Gehry. The museum’s design required the precise cutting of titanium plates to create its iconic, undulating façade. This was made possible using water jet cutting, which enabled the precision and flexibility needed to realize Gehry’s innovative design.

The Freedom Tower, New York

Another prominent example of water jet cutting in architecture is the Freedom Tower in New York. During its construction, WJC was used to accurately cut the tower’s glass panels, ensuring a perfect fit and smooth installation.

The Future of Water Jet Cutting in Architecture

As we look ahead, the role of water jet cutting in architecture is expected to grow even more significant. With advancements in technology, water jet cutting machines are becoming more precise, efficient, and versatile, making them a viable choice for an increasing range of architectural applications.

Innovations in Design and Material Use

The use of water jet cutting opens up new avenues in architectural design. As architects continue to push the boundaries of creativity, they increasingly turn to technologies like WJC to bring their complex and intricate designs to life.

Complex Designs: WJC allows for the realization of intricate designs that would be difficult to achieve with traditional cutting methods.

Expansive Material Use: WJC’s ability to cut virtually any material gives architects the freedom to experiment with various types of materials in their designs, from traditional ones like stone and wood to more innovative ones like composite materials and complex alloys.

Eco-Friendly Construction Practices

As the architecture industry becomes more conscious of its environmental impact, water jet cutting serves as a tool that aligns with eco-friendly construction practices.

Reduced Waste: With its high precision, WJC reduces material waste during the cutting process, contributing to more sustainable construction practices.

No Heat Affected Zones: The absence of HAZ means that there are no changes in the internal structure of the material due to heat, which also reduces the risk of material weakening or deformation.

The Challenges and Limitations of Water Jet Cutting

While water jet cutting offers numerous advantages, it is also important to acknowledge its limitations and challenges in order to provide a balanced perspective.

Cost and Maintenance

One of the primary challenges associated with WJC is the initial cost and ongoing maintenance of the equipment. The high-pressure pumps, abrasive materials, and replacement parts can be costly, which may be a barrier for smaller architectural firms.

Noise and Safety

Water jet cutting machines can be noisy and pose safety risks if not handled properly. This necessitates the use of proper safety equipment and training for the operators.

Conclusion

Water jet cutting has undoubtedly ushered in a new era in architectural design and construction. Its ability to cut with precision, work with a wide array of materials, and align with eco-friendly practices makes it an invaluable tool for architects.

Despite the challenges, the numerous advantages and potential applications of water jet cutting make it a technology that will continue to shape the future of architecture. As we look forward to more innovations in this field, one thing is certain – water jet cutting will remain at the forefront of architectural design, pushing the boundaries of what is possible.