Constructions have been the most important part of the aspects of living and habituating. Constructions not only about the homes, office, parks, malls, etc. but along with that, the most important factor is transportation. So, far humans had discovered many ways of transportation whether by land, water, or air. And also constructed several things related to it. Today we are here to talk about one of such miraculous constructions done by the engineers all across the world. If you are asked a question, which transportation means is the best by your side? Many would say cars, buses, trucks, luxury buses, etc. but the majority among all would be trains or railways.

Rail journeys are always memorable, as for a traveler it has been one of the best experiences. Furthermore, being a child we all have admired rail traveling and air traveling. But have you ever thought about the airy railway? It might feel like a joke to you. But somewhere in India, the world’s highest rail bridge is about to be constructed. You would be shocked after listening to that, “This bridge will be about 359 m above the Chenab River present in Jammu & Kashmir”, and that number is almost 30 m greater than the Eiffel tower present in New York.

Introduction

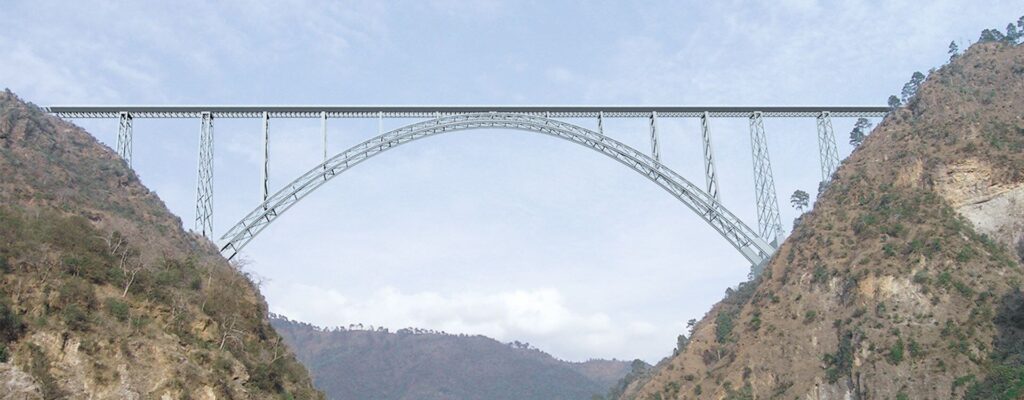

source: wsp.com

Jammu & Kashmir regions have the least traveling access whether it is railways, bus transportations, or airways. Though, keeping this aspect into consideration, India’s Northern railway has summed up and came up with the idea of connecting Jammu and Kashmir. The construction is about to be done between Udhampur and Baramulla, both of them are situated in the Reasi district of the Indian state Jammu & Kashmir. There was a big issue at the time planning, the issue arose because of a large valley present between Udhampur and Baramulla. Usually, the valley is known as the Kashmir valley, further, it is most popularly known as the Chenab River all across.

Not only this, many other geologies are acting as a predicament in this project, they are mountain terrain, Himalaya geology, and many more. But the main geology to be believed is that it crosses the Chenab River.

Planning and Budget set-up

The project for constructing Chenab Rail Bridge came into existence in the year 2008. At first, an arch overpass was proposed. According to the proposal, the details of the project are given below:

Measurement of railway lines was 657 m long (2,516 ft.)

Height of the viaduct was 189 m high (620 ft.)

Average budget cost was 10,00 crore rupees

No. of spans: 13

Longest span: 233 m (764 ft.)

Crosses: Chenab river

Design: Cable-stayed plan

Material: Steel & concrete

Though, the proposal was rejected by the railway committee in 2014. The construction of this project was prejudiced as the cable-stayed conduit, but as it was not meeting the proper requirements and was mismatching some geological aspects of the surroundings the proposal, unfortunately, got abandoned.

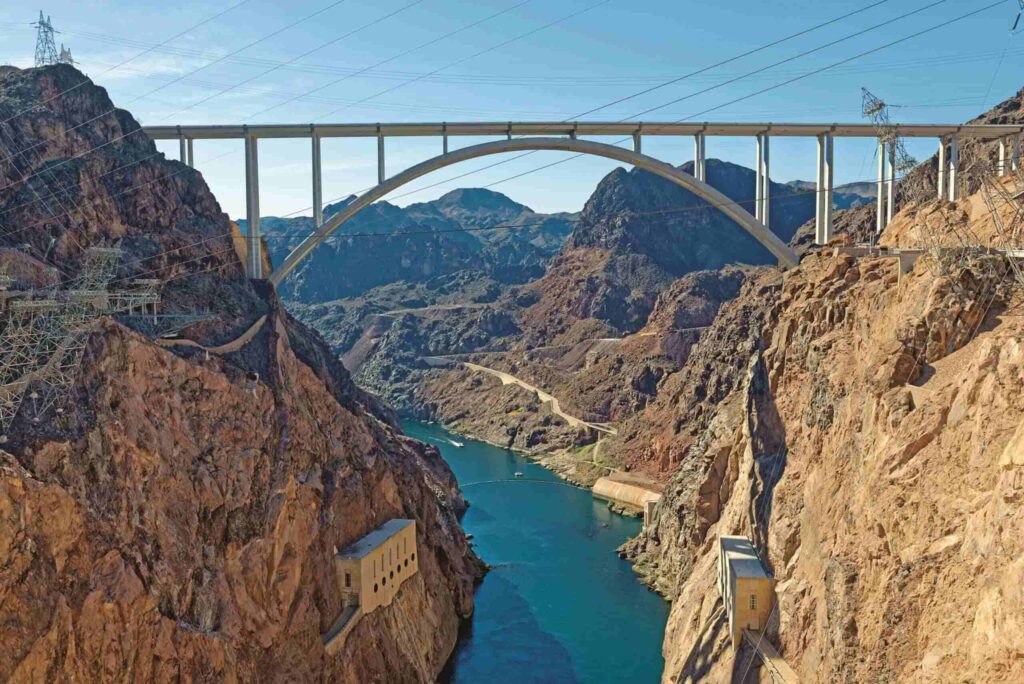

source: flicker.com

After this proposal several new proposals were proposed out of which the proposal passed includes the below-given details in it:

Measurement of railway line 1,315 m long (4,314 ft.)

Height of the overpass 359 m high (1,178 ft.)

Average budget cost 20,000 crore rupees

No. of spans: 17

Longest span: 467 m (1,532 ft.)

Crosses: Chenab river

Design: Arch plan

Material: Steel & concrete

It has been noted that the work resumed in July 2017. And by November 2017, the planning was all set to go on. After planning gets approved, another main step is designing the plan. As this viaduct is going to be the highest rail bridge ever, many national and international codes must be applied to get the plan done successfully.

Designing the plan

After the proposal gets approval, the design of the overpass is a must. While designing certain points have to be taken into consideration they are aesthetics, economy, and availability of material. Thus, keeping all these points and geological conditions into consideration, the local and global expertise made a decision to design this viaduct as a large span single arch steel overpass that is connected via viaducts on either of the sides of the construction. For adding up the utmost strength arches are fabricated with the help of large steel trusses. Furthermore, to make it wind resistant, the trusses are settled and sealed in a steel box. Those steel boxes are then stiffened and filled with the help of concrete. As an exceptional advantage, painting is not required.

For making the design easily maintainable, the engineers have minimized the number of bearings passing viaducts. According to the latest proposal viaduct piers are made of concrete while piers nearer to the arch are made up of steel, as a result, it enhances the riding quality and stabilized inspection becomes easier.

source: usatoday.com

The major arch of the rail bridge requires various additional parameters; they are second-order effects, global stability, fatigue, and much more. Besides all these parameters it must be designed so precisely that it can consistently bear the several loads acting on it. Though, it is important to design it as per the construction standards that are being followed all across the world.

According to the several Indian Construction Institutions like IRS (Indian Railway Standards), IRC (Indian Road Congress), and IS (Indian Standards) they found the design inadequate, as of now Indian Construction Associations have been firm with the simply supported spans connection that too with the maximum span of 100 m. While in this case, the limit has exceeded, for that reason INS (Indian National Standards) had summed up with International Standards like UIC (International Union of Railways), BS (British Standards), and Euro. Not only this, there are many global, versatile, relevant, and experienced experts involved in this project to facilitate it to success.

Let us have a look at the list of design considerations:

Wind load is the major load acting upon the viaduct because of its excessive height measures. For the same, many computation wind loads were taken so that one gets a clear idea about the type of strength they need.

In case if a blast occurs, then probably there could be a chance of demolition of such a gigantic structure, thus, somehow the engineers have come up with an idea of blast resistance design.

As per the standards included in BS codes, several fatigue design tests are done successfully.

Also, the limited state of philosophy has been confirmed with the help of BS codes.

According to the Euro code 8, a detail of the ductility of RCC piers of a very tall and hollow rectangle is allocated.

Provision of LWR (Long Welded Rail) and the calculation of the resulting force are done successfully as per the guidelines of UIC – 774 -3R.

Limits of deformation of the construction with respect to the comfort agenda is being calculated by UIC – 776-2R and UIC – 776-3R codes.

With respect to the IS codes structure redundancy is effectively provided to the structure. Thus, in case of mishaps or one pair failure, the structure will not collapse at all.

IIT Roorkee developed site-specific seismic spectra.

The eminence phase has been emphasized, as the quantum of production and welding is massive. Frequently aboriginal matter obedient to IS codes has been premeditated to be used, whereas, for the blueprint, IC (International Codes) has been referred, which means the eminent organized work is still complicated.

Construction

At first, it was intended that the structure will get completed by December 2009. But as there were various ups and downs in the overall plan of construction and also the new plan which our engineers have come up with have to sum up with different international committees, the work restarted in 2010. Further, it is said that the project was halted in September 2008, as they weren’t able to clarify the viaduct’s stability and safety factors. Though somehow they managed the situation, and as we discussed they started their work in 2010 again, they have the plan with them to complete the structure by 2015.but again, as the internal standards and committees entered in the project it is now intended to be completed in December 2022.

The only reason for summing up with different prostitution was coming up with the best ever plan and design so that it gets succeeded in its first try only. And as we discussed many standards codes were used while designing for the highest rail bridge around the world. After clearing out every aspect with the help of National and International standards. An elder administration executive said, “The plan is maximized in a way that it can grasp up to 266 kmph wind alacrity”.

source: indiatvnews.com

Construction work is given to Top Echelons which is the third-largest constructing site of India. The project accelerated last year and it is been said that Jammu & Kashmir will be connected via railways till December 2022. As of now, Udhampura Katra (25 km), Quazikund (118 km), and Baramulla (18 km) have already been constructed. Along with these entire constructed sites, 126 km out of 174 km has also been completed yet. The last one which is still remaining and is being projected is to be completed by December 2022.

According to officials, it is said that this project got a large push in the last year as there were many projections and campaigns going on at the same time, the project was in need of some expense. Though for the same Prime Minister announced a package of Rs 80,068 crore on November 7, 2015, the package was said to be passed by the act of PMDP (Prime Minister’s Development Project). Also, the pack up introduced was not only for the socio-economic road and rail network of the rail bridge it also includes a range of unbiased provincial improvement of Jammu & Kashmir.

Furthermore, as per the survey taken in the J&K region on August 2019, it is projected that there are still 54 more projects left out which are to be done in the near future, also it is deducted that all those projects had an outlay of almost Rs 58+ thousand crores. Besides those 54 projects, an outlay of Rs 21+ thousand crores was transferred for about 9 projects. The amount was transferred by PMDP which was held in June 2018. Though, these were the only reason due to which there was a rapid and unprecedented increment in the various construction sites.

As of now, from June 2018 to July 2020, it is sustainably perceived that the number of remaining projects has now summed up by 7 only, out of which 9 projects were removed previously. Anyhow the engineers and the officials gave their best, to sum up, all the projects in few times and now there are only 9 projects left to be done, which to is being projected to be done in the upcoming 2 years.

Some of the projects that get completed are:

Rambaugh flyover, Srinagar.

Power transmission line comprising of 220KV passing through Srinagar-Alusteng-Drass-Kargil–Leh have been completed.

Ladakh region gets connected with grid connectivity.

Semi ring road in Jammu is intended to get accomplished by next year, for now almost 30% of the work is done.

Banihal tunnel lengthening 8.45 km is almost 90% completed.

These were a couple of major projects that have been completed or about to be completed. Furthermore, there are many more projects which are under construction or might have got accomplished until now. Though, all these processes are proceeding just with the aspect to connect J&K with the several different regions of India and the world also. And as there were fewer public transportation services so it was difficult to have perfect connectivity. But now one can easily connect any of the parts of the J&K by the means of railways. And this is all possible because of the Chenab Bridge which is the tallest rail bridge around the world.